There are certain things in daily life that are overlooked until they break. One such example is the door closer, which is vital for maintaining regulated door movement and building safety yet is often disregarded. In order to clarify the mechanics and importance of door closers, we will examine their functioning principle in this article.

Let’s take a detailed look at the working principles of the door closers. This will help us take a closer look at how it functions.

A door closer’s primary mechanism is a hydraulic one. It is essentially a spring-loaded mechanism attached to the head of the door. The closer contracts and releases in response to an open door, automatically and precisely shutting it.

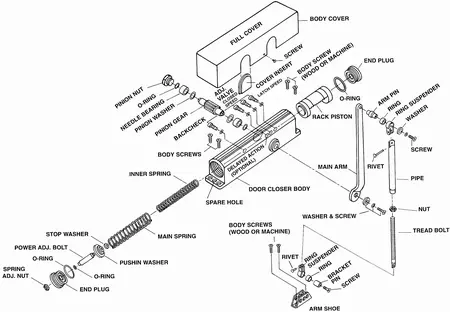

A number of vital parts make up the hydraulic door closer: housings, end caps, sealing rings, connecting rods, one-way valves, rack plungers, throttle valve cores, supporting guides, return springs, transmission gears, and housings. Together, these elements make it easier for the door to open and close.

Opening the door causes the connecting rod to become active, which starts the transmission gear rotating and the rack plunger moving to the right. The right cavity’s hydraulic fluid also compresses as a result of the spring compressing.

Oil pressure causes the left side of the plunger’s one-way valve ball to open, allowing hydraulic oil to pass through the valve and move from the right cavity to the left.

The compressed spring releases its stored elastic potential energy after the door has finished opening. By pushing the plunger to the left, this motion rotates the door closer link and the transmission gear, which finally closes the door.

One-way valve closure and compression of the hydraulic fluid in the door closer’s left chamber occur during the spring release procedure. There is resistance to the spring release because the hydraulic fluid can only exit via designated channels.

By use of throttling, this resistance regulates the pace at which the door closes. Different parts of the door’s stroke may have their closing speeds adjusted by altering the throttle valve.

Now, we’ll take a look at the significance and applications of door closers.

In many applications, door closers are essential because they allow doors to move smoothly and shield surfaces from harm from slamming. Heavy steel doors, especially those with fire ratings, often utilize them since it is crucial that they can regulate door movement and lock firmly.

Door closers operate on the basis of a hydraulic system that makes doors easier to open and shut securely. Door closers are essential elements of contemporary design because they improve building safety and functionality by regulating door movement and acting as a safety precaution against slamming.

A thorough understanding of door closers reveals how crucial they are to maintaining regulated and smooth door movement. Door closers enhance building safety and performance in a variety of contexts by using a range of components and functioning based on hydraulic principles.