Any commercial door closer that gets stuck in the open position creates a security and safety risk that needs to be handled immediately. A defective door closer is a frequent occurrence that can affect building security, climate control and safety regulations, but the good news is that in most instances, the problems can be successfully addressed by proper diagnosis and repair. Engineers will need to troubleshoot.

By breaking down these door-closing systems into mechanical components and solving them one at a time, door closing issues can be eliminated. Whether the problem is as simple as something caught in the hinge or the mechanics of the door itself, or something more intricate like the controls for the door mechanisms themselves, this guide will provide all the necessary information to successfully troubleshoot and fix door closers. Ensure that your business door is secure and operational.

Need help repairing or replacing door closers?

Many commercial doors have door closers, which are complicated devices that ensure the reliable closure of the door after every use. As is common with most machines, if a door closer gets stuck in the open position, this usually points to one of a few possible problems that can be discovered through proper and methodical evaluation. All of this helps in knowing certain issues that can save both time and money in making repairs without having to make a call for professional assistance.

Before going to the more specific parts of the solutions, do the following steps first:

The common reasons for the commercial door closer being stuck in the open position are:

Step 1: Check for Immediate Obstacles

Evaluate Potential Access Limitations Prior to concluding about a mechanical breakdown, try to check the environment and the area around the door:

Step 2: Inspect the Door Closer Mechanism

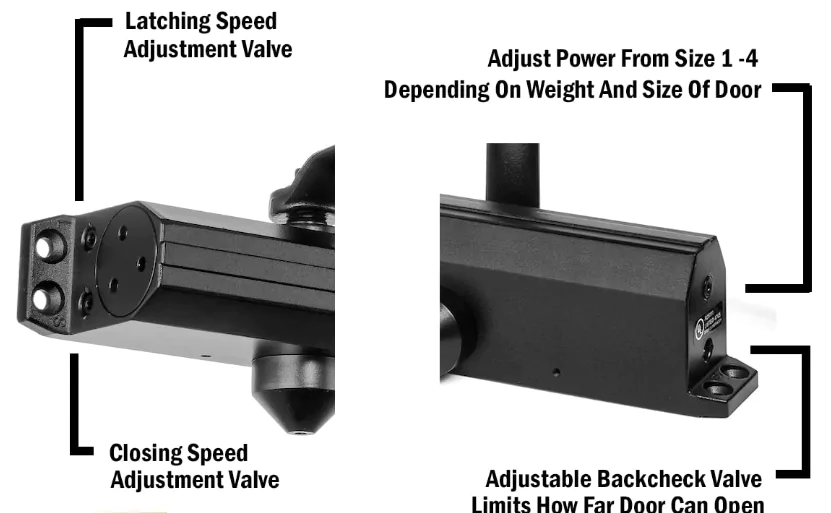

Examine the Mechanism of the Door Closer Inspect the components of the door closer in detail:

Step 3: Evaluate Door Alignment

Looking at the Door Alignment Closer problems can also be brought about by the fact that the door has not been aligned properly:

There are two primary components of a door closer leg system that controls the door’s movement, namely the forearm and main arm. These two components are mechanically joined by enough hardware to ensure there is no rough movement when the door is being operated or controlled. When performing an arm inspection, the practitioner should focus on, but not be limited to point contacts, pivot joints, or any mechanical linkage to the door frame as these might be the most prone areas to wear out. Generally, there are two primary components of a door closer leg system that controls the door’s movement, namely the forearm and main arm.

A malfunctioning spring may prevent the door from returning to the closed position. The appropriate way of testing the spring mechanism is by:

Spindle connection is a core component that determines the door closer’s effectiveness. Consider checking these things:

In cases where the alignment is wrong and has to be:

People interpreting performer’s information will additionally solve a lot of injuries, which appeared at the door closers working areas. However, performing repairs on the hydraulic fluid service conduct and other complicated issues like internal spring breakage, doors’ structural issues are meant for skilled technicians with proper equipment to carry out the repairs.

In order to avoid these concerns:

A number of different factors come into play when deciding whether a door closer should be repaired or replaced entirely. It is not unusual to have to replace a door closer that is over 10 years old, or if it costs more to repair than 50 percent of the price of getting a new one. More often than not, when two or more accessories are in bad condition or replacement costs and installation are inexpensive in comparison to the long-term worth of the asset, replacement is the best option.

Having a commercial door closer that is stuck open and recreational activities are encouraged, begins with knowing the extent of the Restoration that is needed. Things like basic adjustments and obstructions can be salvaged and done in house, and more serious complications such as internal mechanism repair should be contracted to skilled technicians where safety and operability can be assured.

There are a number of factors that should be considered when deciding to repair or replace a door closer. The first consideration is the age of the unit: how much time has it affected? How applicable are the repairs, in fact, to Ray’s replacement? Cost-benefit considerations, such as in units with multiple issues, and units over eight to ten years of age often replace better in the end.

In order to avoid new problems in the future, a regular basic maintenance schedule needs to be carried out. The program should include, at a minimum, a monthly visual inspection, a quarterly operational inspection and a yearly inspection by professionals. Recording sheets of all maintenance performed serves as a good measure for forecasting the workings of the unit and even avoiding problems before they materialize.

To achieve maximum efficiency and longer life span of the door closers, the following should be adhered to:

Quality should be the overriding issue when recommending back-up parts or door closers. Door closers of high quality such as those made by OUDE are packed with high endurance and efficiency. Door closers by OUDE are made with modern-day technology that ensures they perform consistently and last longer.

In terms of safety risks, operational nuisances and general circumstances of every door in a building, proper functioning of the door management system is everything. Most problems are thorn-in-the-head and can be managed with a controlled examination and basic techniques in maintenance, but some problems do require professional knowledge and skill.

If satisfaction is desired from door closers over a long period, it is ideal to source them from quality, certified manufacturers such as OUDE, which is a recognized brand worldwide. A variety of different applications are available within their line of door closers, as all are focused on optimizing function and reliability while requiring minimal maintenance. For door closing devices, installation as well as maintenance, please visit OUDE’s website for their range of commercial door closer solutions and other requirements.