Door systems with mechanical means of closure are of paramount importance in the contemporary context of safety and usability of construction elements. Simultaneously, the automated and hydraulic systems of door movement must comply with many different states’ standards. Two corps. OUDE has been well-experienced for over twenty years; the company is one of the leaders in producing door-closing devices that meet these critical requirements.

The certification of door closer standards primarily involves ADA accessibility certification, UL10C for fire door certification, BSI 1154:1997 for European certification, and ANS 156.4 for American certification of standards. These requirements must be met in order for a building design professional, a building operator, or a security professional to understand how to effectively combine regulation with a building’s integrated functions.

Explore ANSI & UL-certified door closers – Contact OUDE today!

Door closers are mandatory and must adhere to a certain standard as set by different governing bodies and institutions. These include the following:

ADA (Americans with Disabilities Act): Details standards regarding usability

UL 10C: Specifications including requirements and associated tests regarding fire rating.

BS EN 1154:1997: Controlled door-closing devices developed in Europe.

ANSI 156.4: The American National Standard for Door Controls and Door Closing Devices.

Each standard relates to a specific feature of the door closer, such as its efficiency and safety performance, thus providing a guideline for manufacturers and installers.

These standards are not implemented merely as a matter of regulatory obligation – they are about achieving:

Safety: Saving the users of the structure during fire accidents.

Accessibility: Making sure that the doors are usable by all.

Durability: Guaranteeing long-term performance

Reliability: Operability under different circumstances.

OUDE is committed to quality, as evident from our CE, UL and ANSI certifications. Our closers are subjected to a number of tests as well as quality control inspections to ensure that they meet and surpass international standards.

| Standard | Focus Area | Key Requirements |

|---|---|---|

| ADA | Accessibility | Open force limits and closing speed |

| UL 10C | Fire Safety | Fire resistance and positive pressure testing |

| BS EN 1154 | Performance | Durability cycles, door mass, corrosion resistance |

| ANSI 156.4 | Overall Quality | Operational testing, closing force, and finishing requirements |

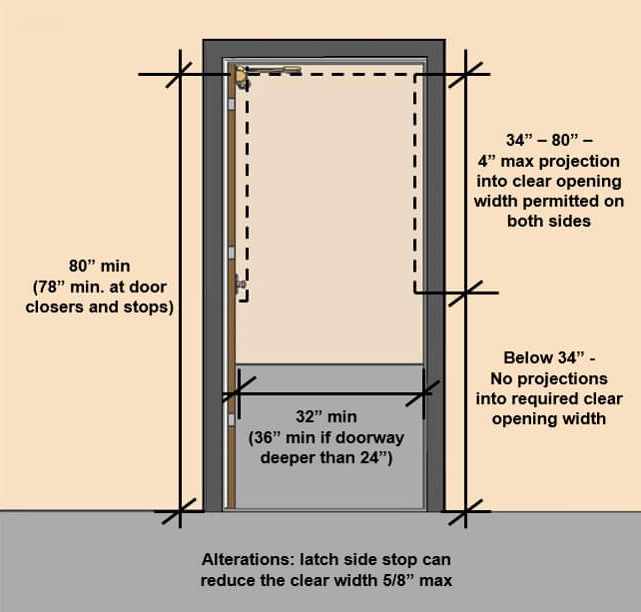

According to the Americans with Disabilities Act (ADA) there are certain parameters that have to be followed in regard to door closers:

Why Choose OUDE Door Closers?

OUDE possesses technical know-how and stringent quality control, thus being able to provide clients with door closers that satisfy various international norms:

- Has successfully met the requirements of the EN 1154, ANSI/BHMA A156.4, and UL 10C standards and has certificates.

- Produced with modern technologies in high-tech factories with the corresponding test laboratories.

- Has over twenty years in the industry.

- Has a detailed quality inspection system with detailed instructions and standards.

There is a definite but low-rating fire doors and door closers installed on them should be UL 10C rated fire door closers. The main requirements include the following:

The Americans with Disabilities Act is a critical piece of legislation for all door closers because it identifies key limitations or standards which would make these doors absolutely usable by everyone. This includes people with disabilities. As such, OUDE’s closed systems, particularly the 1000 Series and 8100 Series, are able to function within these parameters in a substantive manner, and are therefore manufactured to meet these practical access requirements.

BS EN 1154:1997 breaks down the classifications into a six-digit classification as follows:

This classification system is employed in order to make certain that door closers are able to meet the intended performance and safety features for the doors they are used on.

Fire safety is one of the major considerations when it comes to designing buildings and as part of the fire-rated devices, UL 10C is the most important certification for door closers. Some of the products that OUDE offers include UL-certified door closers such as:

The European standard, BS EN 1154:1997 employs a complex six-figure code of classifying numerals for door closers and their subsequent fittings. Our products in general and EU-approved ones in particular satisfy these norms.

| Classification Digit | Meaning | OUDE Compliance |

|---|---|---|

| Digit 1 | Category of use | Grade 3-4 |

| Digit 2 | Test cycles | Grade 8 (500,000 cycles) |

| Digit 3 | Door mass/size | Multiple size options |

| Digit 4 | Fire behavior | Grade 1 for fire doors |

The American National Standards Institute’s 156.4 is a very important complement to the high quality and performance of door closer devices. Manufacturing company OUDE puts its products through reliable testing and passes the following tests:

OUDE has a modern manufacturing setup providing uniform quality across all product lines. The modern testing facilities allow for:

Healthcare establishments are seen to have the highest need for door closers’ performance because of the operational environment’s peculiar needs. Doors Closers made by OUDE are purposefully designed for the highly demanding and hygienic environment associated with the medical field. Our 5000 Series has a special finish that is antimicrobial, and has mechanisms that are made to close doors on good performance, featured in hospital corridors subjected to lots of traffic.

Most of these door closers are suited for bed closing in patient rooms where silence is desired by the health professional’s career. The combination of these two factors: ADA regulation adherence and infection control, make these units extremely appropriate for usage in healthcare institutions where accessibility and high hygiene standards are major issues.

It is to be noted that educational setups provide special deterrents in regard to the application of a door closer where a consideration has to be placed regarding safety, strength and usability. OUDE’s 8100 Series specifically provides for these factors by offering strong construction with daily use of a particular door closer and still being in compliance with ADA.

There are a wide variety of opening and closing systems for doors located within educational institutions, hence, the door closers must be suitable for the type of environment they will be used in. Our products have an adjustable end stroke and a backcheck to prevent demolition of walls and adjacent appliances owing to robust students.

A single set of closers that would work well with the varied climatic conditions of the lot’s doors and gates would require a lot of research. In modern commercial architecture, a phenomenon is introduced quite often which is related to the so-called upgrades and remakes of existing ones, which requires me.

OUDE’s commercial-grade door closers are able to meet any challenge handed to them as they are capable of withstanding high volumes of business wear and tear. This is best for buildings not only in congestion but definitely those in high traffic, because the units can be changed from one extreme to another without overheating. As a result, many certification requirements can be embodied in one unit, which makes specifications and installation work easier, faster and cheaper for managers and contractors of buildings.

Taking into account safety issues, it is not unusual for large doors in industrial buildings to be installed with door closers. OUDE’s heavy-duty door closers range is more suitable for manufacturing and warehouse units, which are designed specifically with increased corrosion protection and strengthened structure.

Such doors are designed for use in areas with extreme temperature fluctuations and high dust concentrations. Mechanically, contamination of internal structure is avoided with advanced sealing technology allowing successful long-term service in harsh industrial environments.

The same functions are required of the closers but placed in a more presentable manner where the amount of aesthetics is the deciding factor and security functions must as well be used. OUDE extends the idea further with its designer series with an emphasis on stylish finishes and concealed mounting, while the safety requirements are met.

A feature of these door closers is fully adjustable closing forces, which is needed when air pressure conditions are extreme and when controlling the room temperature. Using noise reduction technology would allow keeping comfort for the guest without compromising security and fire prevention.

In residential applications, such doors may require usage that provides security without too much effort for access by all users. OUDE’s residential series meets the requirements by having small dimensions and working quietly in the context of apartment houses and condominiums.

These units incorporate temperature compensation valves that are designed to maintain optimal performance during seasonal changes. With the visual aspects being harmonized with the usage of doors and being photographed, these door closers are acceptable for new house construction where glass and modern aesthetics prevail.

Today’s building codes and accessibility requirements will not be complete if the door closer standards are omitted. These standards determine the heretofore mentioned door control systems’ capability to operate correctly in emergency scenarios or physically challenged access on doors.

OUDE complies and goes beyond these standards, therefore demonstrating our commitment to quality and safety in the production of door hardware. The need to look for a door-closer company that has all the necessary certificates today is very high as the market gets more complex. Thanks to OUDE’s vast product line, which has passed rigorous quality assurance, these products are manufactured in line with existing market requirements while preparing for changing market needs. Please view the entire catalog and talk to our technical experts for specialized door closer applications that meet your requirements and specifications.