Heavy-duty door closers are indispensable components in contemporary building security and safety systems, ensuring complete control of the doors in challenging environments. These modern systems provide enhanced strength, advanced locking mechanisms, and better control, providing greater accuracy and reliability over standard door closers.

Choose OUDE heavy-duty door closers for enhanced security and durability.

With the increasing complexity of structures and the ever-escalating security features, the selection of a door closer has become an area of particular concern for facility managers and building owners. OUDE, specializing in door closer manufacture for over 20 years, has the view that proper door control is not only a matter of comfort but crucial for safety, security, meeting building regulations and providing durability.

This is an aspect quite often overlooked in the design of most modern buildings today. However, some considerations have brought about the need for these devices. Door closers are not simply convenient devices; they are integral to the building and its security. The use of incorrect door closers comes with foreseen risks for the building, including:

When it comes to door control solutions, heavy-duty door closers are considered the best in the industry since they are designed for demanding applications where reliability and long-term use is critical. These devices, which are designed for heavy operations, are capable of the following:

Heavy-duty door closers, such as those offered by OUDE, have been developed further and now have features such as:

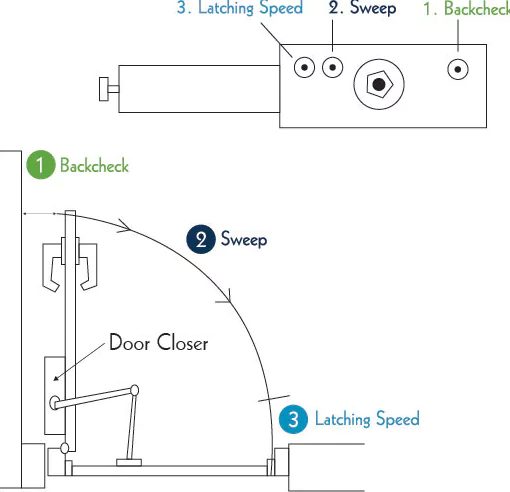

Adjustable Closing Speed: Lets you remotely adjust the closing motion of the door.

Backcheck Control: Allows aggressive door opening without inflicting harm.

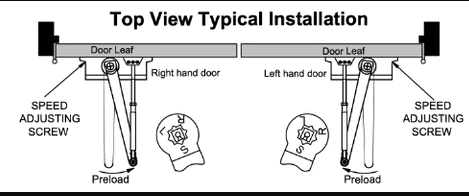

Multiple Mounting Options: Permits other alternative positions for mounting on other doors.

Temperature-Independent Performance: Functions well regardless of climate conditions.

The OUDE Advantage

The design of all our industrial-grade door closers manufactured by OUDE was developed with the principles of innovation and reliability. Our products are subject to stricter testing and certifying procedures such as:

- ISO 9001 certificate for quality management

- CE certification for European standards

- Tests of durability in a variety of conditions

- Environmental impact and sustainability evaluation

The main aspects that differentiate heavy-duty off-the-shelf and standard door closure units are their structure, capacity, and design elaboration. Our heavy-duty door closers have a dimensional understanding of how these products are to be placed for utmost reliability in every application.

Heavy-duty automatic interior door closers are constructed with better materials because of the requirements of the end user:

These heavy-duty door closers from OUDE have weight expectations that match the heavy weight from the rest of the lineup:

The key differences include:

Heavy-duty: For high-traffic zones. More than 1000 cycles a day.

Standard: Most appropriately used in areas with low to medium traffic

Ordinary door closers usually allow for a minimal degree of speed adjustment, with nearly no control over variations. Also, the closing speed is set within a relatively much narrower range than would be ideal for most settings.

OUDE’s heavy-duty door closers are equipped with the following cutting-edge features:

heavy-duty door closers are quite good when it comes to security manual requirements:

Standard door closer speed typically involves:

OUDE’s heavy-duty door closers are suited for:

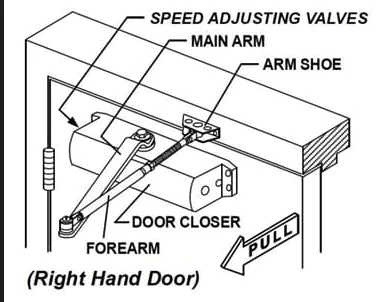

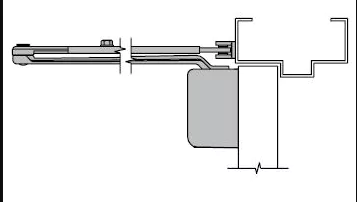

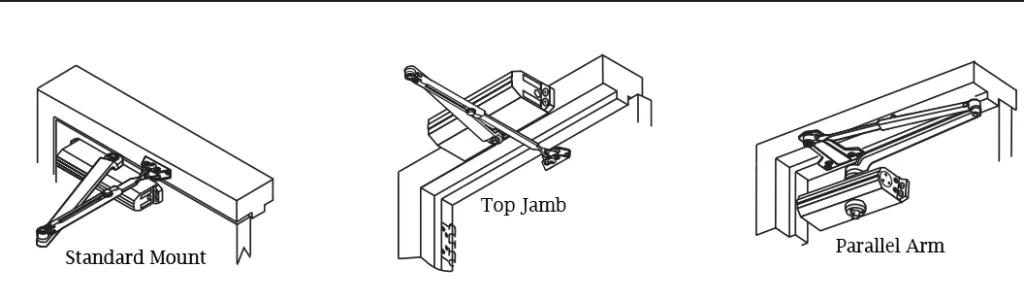

Our heavy-duty door closers have four different separate mounts:

Every method of installation takes proper consideration of the door mechanics to provide over-performance without compromising the function of the door.

Legal requirements of building codes must also be satisfied while picking such a device. The strongest obligations include:

A heavy-duty model can be considered in the case of the following applications:

Why Choose OUDE?

OUDE has more than 20 years of history and is constantly improving in such directions as:

- ISO 9001:2015 certification

- EN 1154 compliance

- Presence of its distribution network all over the world

- Possessing the most advanced Research and Development in the industry

Service of heavy-duty door-closing devices is necessary to provide good operating characteristics and prolong the service life. OUDE services include:

This section will briefly introduce the common issues, maintenance and troubleshooting of the door closer:

Initial Investment vs. Long-Term Value

It is acknowledged that heavy-duty door closers are costly in the short run after their purchase. However, with such a purchase, long comparisons can be made of the joules of the forward.

The installation of heavy-duty door closers increases the energy efficiency of buildings because they assist in:

When choosing a heavy-duty door closer, several considerations must be taken into account. Among these include the frequency of usage, the weight of the door, the environment, and the need for particular security. The proper selection could greatly strengthen the protection of the building, enhance the economy of power consumption and safety regulations with their application, and serve for many years.

OUDE offers a broad selection of heavy-duty door closers for every need, because of extensive testing and certification and experience in the field. Moving towards the future, OUDE remains committed to constant innovations, upholding excellent standards, and giving customers the attention they deserve, achieving maximum efficiency of doors control in construction works.